Did you know that NASA is at the forefront of vertical farming research? NASA invented aeroponics for astronauts to grow plants in space. Thanks to their innovation, farming researchers are changing food production as we know it.

NASA started out looking for a way to farm plants with minimal water and no arable land. Today, they focus on how to grow plants on future expeditions to the moon and mars. Thanks to NASA’s vertical farming research, CEA has taken many giant leaps for mankind.

What is CEA, you say? Well, my good reader, it stands for «Controlled-Environment Agriculture». If you want to know more, check out our article about why the CEA business grows so fast.

NASA’s research team is far from the only one looking into vertical farming. Huge companies, many universities, and even governments are keenly interested in vertical farming.

Microsoft Research, for instance, invests heavily in vertical farming research. In particular, they develop AI for plant growth automation. Microsoft’s researchers believe vertical farming might prevent a future global food crisis.

Read on to learn more about the future of food production and the research that keeps improving the vertical farming business.

Contents:

- Research on AI automation in vertical farming

- Global benefits of vertical farming research

- The vertical growth of our future food industry

Research on AI automation in vertical farming

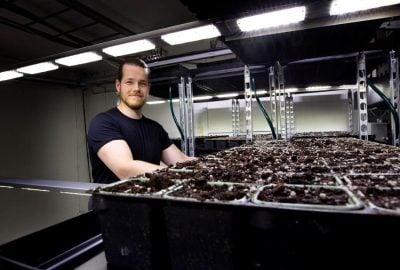

Until quite recently, traditional farming was more cost-effective than vertical farming. Many succeeded in turning a profit from vertical farming, but it took some creative marketing to get it done.

Luckily, vertical farming is relatively easy to promote because of its sustainable potential. Also, people will gladly pay extra for pesticide-free, high-quality plants. It is, therefore, a good idea to set the price higher than plants from traditional farming.

On top of this, plant science has made many breakthroughs in the last couple of years. As a result, vertical farming is more cost-effective than ever before. In particular, LED technology and plant growth automation have brought down the costs of vertical farming.

Related article: Why LED grow lights are best for vertical farming?

Ken Tran is a principal research engineer at Microsoft. According to Tran, vertical farming got a lot more efficient when they discovered how to process large amounts of precise data in a much shorter time.

The key to this discovery was new AI technology. The sensors in the plant growth systems gathered large amounts of cloud-processed data.

This allowed the AI to adjust the grow lights to perfectly balanced plant growth and minimal energy consumption. A similar process was used to adjust the levels of plant nutrients in the growth systems.

Plant optimization automation

Eri Hayashi of the Japan Plant Factory Association develops plant recipes. She describes these recipes as plant requirement lists. One of the biggest challenges in her job is that plant growth optimization relies on numerous conditions.

She needs to consider lighting, watering, nutrients, C02-levels, and more. Because of the many factors to consider, Hayashi has only completed a handful of plant optimization recipes. However, new AI technology has sped up her work.

Analyzing thousands of plant pictures used to take many hours. Now, thanks to machine learning, surveillance takes a fraction of the time. But automated problem-solving in vertical farming isn’t the only benefit.

The latest developments in Ai technology let us fully automate urban plant production. It allows for reorganizing food storage and delivery logistics in densely populated areas. The result is strengthened local food production.

Ken Tran thinks apartment complexes might be fitted with individual indoor farms within the next decade. He also believes that home delivery of vertically grown fresh produce will be available sooner rather than later.

Right now, we are fully capable of delivering vegetables to your doorstep that were harvested only two hours ago. According to Tran, it is only a matter of time before plant delivery is as common as pizza delivery.

Related article: Vertical farming vs. traditional farming

Global benefits of vertical farming research

UN predicts the global population to reach 9.7 billion by 2050. In other words, there will be 2.3 billion more mouths to feed in the next 28 years. Not only that, but most of these people will live in urban areas. The demand for food will rise accordingly.

The food industry faces an insurmountable challenge as the meat demand will be impossible to satisfy. Rapid urbanization will leave little arable land for animal food production, resulting in a severe food crisis.

On top of this, research tells us that our current agriculture is responsible for 24 percent of all greenhouse gas emissions. Food transport causes some of these emissions. However, they will primarily be eliminated by urban, vertical farming.

In theory, indoor farming offers a sustainable option for food production. It won’t solve the coming food crisis or stop environmental breakdown on its own, but it will prevent further exploitation of our natural resources.

A research team from Universiti Kebangsaan Malaysia studied the environmental effects of vertical farms in urban landscapes. They found that big-city indoor farms absorb C02 and increase oxygen levels.

Pumping C02 into vertical farms speeds up plant growth and promotes healthy photosynthesis. The byproduct of photosynthesis is oxygen. In this way, vertical farms can make constructive use of greenhouse gases.

Related article: How vertical farming reduces environmental impact

The Energy Consumption Problem

Vertical farming can still do a lot better. It is true that indoor agriculture saves space and uses 70-95 percent less water than traditional agriculture. But the energy consumption still needs to be reduced.

A focal point for vertical farming research teams around the globe is energy reduction. LED grow lights technology has come a long way in the last couple of years and successfully reduced energy consumption in vertical farming.

AI research has also proven helpful. In this case, machine learning detects unnecessary use of electricity. As such, it always keeps the growth system power consumption as low as possible.

To further lower energy costs, vertical farming research on light intervals has shown potential. The theory is quite simple: Plant optimization can still be achieved by using smaller grow lights and turning off the lamps at the correct intervals.

The key is to find the perfect balance between minimal lighting and optimal growth. Not a ray of light shall go wasted. It might be a temporary solution, but it’s the best we’ve got at the moment. Plant scientists are on the case, however.

Some bright minds have suggested creative use of solar panels as a solution. Also, this idea is quite simple: First, charge your batteries with solar panels in the daytime. Then, readjust your panels to absorb light from your LED grow lights at night.

In theory, this could allow the solar panels to charge your batteries 24/7. For the time being, this remains an untested theory. It could be a shot in the dark, but ideas like this maintain forward momentum in vertical farming research.

The vertical growth of our future food industry

Research and business often go hand in hand, and the indoor farming industry is no exception. Commercial interest fuels the vertical farming research community. The strides in plant science are funded by companies who believe in its potential.

Whenever a new research breakthrough comes along, new companies get interested. This interest increases market competition, which raises the demand for research and new breakthroughs from vertical farming research.

In other words, the research teams at Microsoft and NASA cultivate a lot more than indoor plant growth. They are making a multimillion-dollar industry. The United States is one of the foremost developers of the vertical farming industry.

Some of the largest indoor plant companies in the world are found in the US, such as Plenty, AeroFarms, and Bowery. Surely, you’ll recognize some of their most prominent investors, such as Google, SoftBank, and Jeff Bezos (founder of Amazon.com).

To put things in a financial perspective, let’s quickly look at some numbers. In 2021, Bowery Farming raised $300 million in funding. In 2020, Plenty landed a deal with SoftBank, which secured $140 million in funding. Before this, in 2017, Jeff Bezos and other investors had already invested $200 million in Plenty.

Related article: What does vertical farming mean to investors?

Plenty for all

Plenty is interesting because they’re making headway in both industry and research. The last development happened in January 2022, when Plenty went into business with Walmart.

Plenty’s plants are already available at Albertsons and Whole Foods. In addition, American consumers can order Plenty’s products for home delivery at Instacart and Good Eggs. By 2022, Walmart plans to make Plenty’s plants available all over the US.

As such, Plenty takes the lead in commercializing indoor plant growth. They show us how vertical farming companies will take over certain sectors of our future food industry.

This leads us to the Bloomberg prediction of the vertical farming industry: According to a BIS research study of November 2021, the global vertical farming market will reach $19.86 billion by 2026.

Plenty’s business model is important because it proves that vertical farming has vast commercial potential. Their deals with Amazon/Whole Foods and Walmart pave the way for large-scale productions.

Large-scale production is essential because huge sales promote cost-effective plant cultivation. More importantly, it allows vertical farming factories to offer competitive pricing, eventually securing a foothold in the global food industry.

Related article: Vertical farming economics in a nutshell

Conclusion: The future of vertical farming research

Indoor plant growth and vertical farming will become a part of our future food industry. Right now, vertical farming research is hammering out the final kinks. However, it won’t be long before vertical farming is thoroughly commercialized.

As soon as plant researchers find a way, and they will find a way, production costs will decrease. Also, plant selection will increase, plant growth optimization will improve, and environmental breakdown will decline.

Related article: Vertical farming’s biggest challenges

The prospects of our future food production are exciting indeed. Vertical farming will breathe life into concrete jungles and turn condemned buildings into green lungs. Call it a big-city transplant, if you will, for it is truly replacing the old with the new.

Thanks to the bright minds of vertical farming research teams worldwide, we might all buy fresher, healthier, and tastier plants than ever before. And best of all, we might buy it soon, in our very own backyard.

Resources

BusinessWire: Plenty Secures $140 Million in its Series D Financing Round

CNBC: Walmart makes an investment in vertical farming start-up Plenty

Hortibiz: How recycling renewable energy can benefit indoor farming

MDPI: State of the Art of Urban Smart Vertical Farming Automation System: Advanced Topologies, Issues, and Recommendations

Microsoft Features: Indoor vertical farming in Asia and beyond: Digging deep in data

Nasa: NASA Research Launches a New Generation of Indoor Farming

Science Direct: Techno-economic-environmental analysis of solar/hybrid/storage for vertical farming system: A case study, Malaysia

Tech Crunch: Indoor farming company Bowery raises $300M