Vertical farming startup costs have stopped many v-farming investors from starting the venture of a lifetime. At Avisomo, we’ve worked hard to develop vertical farming solutions that circumvent high startup costs. In the process, we developed a world-class plant factory automation system.

Giant corporations worldwide invest vast amounts in massive plant factories and successfully turn vertical farming into big business. However, starting a vertical farm from scratch is a different ballgame. At Avisomo, we make startups of vertical farms as risk-free as possible.

What is so special about our solutions? For one, the Avisomo system is uniquely flexible, and secondly, it enables cost-cutting that very few vertical farming solutions can compete with. The combination of super flexibility and remarkable cost-cutting gives all plant factory startups a perfect launch.

The flexibility allows you to start small, learn the craft, ensure that the plant growth is optimized, and secure profits before you expand production. Then, you can scale your plant factory with minimal risk. Total automation equals a minimal required workforce, which cuts your costs to the bone.

Read on to learn more about reducing vertical farming startup costs. Don’t miss out! Take part in the most significant agricultural revolution since the invention of the tractor.

Related article: How to start vertical farming?

What are the vertical farming startup costs?

No matter the industry, keeping up with the latest developments is essential to stay ahead of the competition. This is what vertical farming is all about; making use of the latest advances in agricultural science.

Unfortunately, this means that to stay ahead, you need to invest in the latest technology, and you have to update said technology when improved by researchers and plant scientists. Naturally, this cranks up vertical farming startup costs, but it can be reduced and has many advantages.

In a nutshell, vertical farming startup costs are building cost, vertical farming system cost, power cost, employee cost, growth medium/seeds cost, and delivery/transport costs. We’ll get into some actual numbers in a bit, but first, let’s consider the most significant upsides of such an investment.

Though vertical farming startup costs might be high, the day-to-day production after that will be minuscule compared to traditional farming. For one, plant factories make much better use of space. Vertically stacked crops mean that you can grow large amounts of plants in very small spaces.

Another advantage is total control over plant growth conditions. Vertical farming eliminates seasonal growth. Indoor conditions are easily kept stable year-round, giving you complete control of results and planning for further expansion.

Sounds pretty good, right? Here are the components of Avisomo’s plant factory solutions.

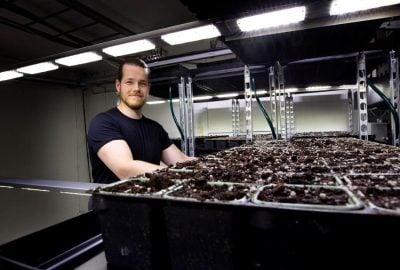

Cost-cutting resulted in world-class plant factory automation

On top of the advantages above, vertical farming’s potential for automation can make for incredibly cost-efficient production. This is crucial since all vertical farms and plant factories have unavoidable expenses. The key to success is to limit these expenses as much as possible.

The first step towards secure profits is correctly setting up your plant factory. Then you stabilize the plant growth. Once that is done, you can cultivate huge crops with less workforce than conventional farming requires.

In other words, vertical farming and large-scale production in plant factories radically alter plant growth efficiency. It is all about producing more with fewer resources.

Crop sensors can digitally fine-tune the conditions in your growth stations to perfection. This minimizes production losses and promotes efficiency. In addition, the latest developments in LED technology significantly reduce the energy consumption in vertical farming.

Avisomo also provides «plant recipes» for automated plant growth in our unique farming systems. The plant recipes are first loaded into your digital control panel. After that, you can easily regulate the plant growth from your PC, pad, or smartphone.

Sign up for our newsletter and get notified when our upcoming articles about plant growth automation, robotics, and plant factory software are published.

Avisomo’s vertical farming system in a nutshell

Avisomo makes vertical farming as efficient as possible. We’ve achieved this by standardizing all components and sizes in our farming systems. As a result, indoor farming has become easy to plan, assemble, supervise, and maintain.

The crops grow in CC trolleys, a standardized unit in plant-growing communities worldwide. Using these trollies, we have designed a system called the Avisomo Growth Station™.

Since the trollies are already standard, they can accommodate all kinds of placement, lighting, logistics, and the number of stacked layers. This flexibility is key in circumventing vertical farming startup costs since it enables you to start small and stabilize profitable routines before scaling up.

Moreover, the flexibility of the Avisomo farming systems is ideal if you want a gradual transition from conventional farming to vertical farming. You can easily combine our farming systems with other types of agriculture. It will not interrupt ongoing plant production.

Standardized components make plant growth predictable. The hardest part is to install the vertical farming systems. When that is done, plant growth automation by plant recipes is a walk in the park.

The best plant trays for CC trolleys are called «1020 standard». These trays are 25×51 cm in size and are easily adaptable to most vertical farm machinery. Each CC trolley can be vertically stacked with four layers of 1020 standard trays.

Avisomo’s digital plant recipes consider whether the plants grow in sod, Rockwool, perlite, or other growth mediums. This makes hydroponic plant growth neat, clean, and with very little need for maintenance.

Furthermore, Avisomo is fortunate enough to have several exciting business partners. Because of this, we can deliver machinery, ventilation, irrigation, lighting, and most equipment needed to get your startup off the ground at a very low cost.

What are the benefits of Avisomo’s vertical farming solutions?

Flexibility is the whole point of the Avisomo vertical farming system. Our goal is to make it possible to start small and gradually gain the know-how required for success. Then, when your plant growth abilities are up to par, you can expand the production into a full-fledged vertical farming business.

Avisomo strives to streamline vertical farming start-ups and transitions to plant factories. We provide everything you need to start vertical farming, including in-house developed plant recipes.

Check our website for more information about plant optimization and business tips for vertical farming companies. For instance, you can learn how to make ideal conditions for plant growth in vertical farms?

When you buy an Avisomo vertical farming system, you also become our partner. This means we will take you under our wing and do everything we can to help you succeed.

What can be grown on vertical farms?

It is possible to grow many types of plants on vertical farms. However, some plant types are better suited for vertical farming than others. Choosing the right ones will reduce vertical farming startup costs since it allows for quickly stabilized plant growth. This is all the more important in the early phases of production.

In short, salads, herbs, microgreens, and berries have the best earning potential. It is also worth noting that plant germination on vertical farms can be very profitable.

Find out more about what plants you can grow on vertical farms

How profitable can vertical farming be?

Many factors are in play when predicting profitability and calculating how to reduce vertical farming startup costs. To illustrate what kind of numbers to expect, Avisomo set up a test center at our facilities. There, we produce and sell many types of salads, herbs, and microgreens.

The Avisomo test center consists of 15 farming stations, all of which have a growth area of 11 square meters. Per the Norwegian Agricultural Extension Service (NLR) recommendations, we placed the pots 15 cm apart. This amounts to a total of 378 pots.

Avisomo’s digital plant recipes cultivate leafy greens and herbs with a 30-day growth cycle, while microgreens have a 10-day growth cycle.

Under these conditions, Avisomos herb production generated an average of 2.640 NOK ($299) per month per farming station. As for salad production, it earned 2.160 NOK ($244) per month, while monthly income from microgreens amounted to 23.040 NOK ($2.610) per month.

These were our profits after deducting all expenses. (Electricity, manual labor, rental fees, and maintenance.)

It is important to note that Avisomo’s test site is tiny compared to your average size vertical farm. Later in this article, we’ll dig further into expected profits from vertical farming. But first, let’s use the numbers from the test site to set up an example of how much you can make from full-size plant factories.

What are the post-startup costs in vertical farming?

Avisomo’s vertical farming system includes all software needed to automate temperature, lighting, and water systems. The software also aids your logistics and simplifies many everyday tasks. Our goal is to reduce the need for internal communication, which reduces the risk of human errors and other defects.

The plant recipes take care of a lot, but we’ve also left room for customization. This means that you are free to create your own plant recipes to ensure optimal plant growth for your particular conditions. Though most vertical farming tasks can be automated, some staffing is always required.

Personnel needed to run an Avisomo vertical farming system

If you set up our vertical farming system for full automation, one person can operate 550 growth stations. The work will mainly consist of system supervision, maintenance of machinery, and problem-solving.

Even non-automated farming systems minimize manual labor by using nifty tools. For example, vacuum seeders, sensors, fertilizer dispensers, and cleaning rooms will keep the workload low.

Avisomo’s non-automated vertical farming systems are designed for one person to operate 80 farming stations. This means one person can carry out all manual labor and maintenance of 80 stations.

Operating costs for indoor farming

What kind of plants you grow determines the price for plant growth materials. That said, indoor farming usually requires the following supplies: Pots, growth medium, seeds, fertilizers, pH-fluids, and possibly CO2.

Depending on your chosen method for indoor farming, these supplies will come at different costs. However, Avisomo’s vertical farming systems are flexible and give you plenty of options when setting up your indoor farm.

The growth materials price will be quite different if you choose Rockwool, for instance, and grow your plants in water rather than soil.

Example: Plant growth materials estimate for crispy salad production in pots.

- Price per seed: 0,3 NOK ($0.03).

- Price per pot: Between 0,3 and 1,5 NOK ($0.03-0.17).

- Plant medium per pot: Between 0,5 and 2 NOK ($0.06-0.23).

- CO2 prices depend primarily on the size of your growth room, but a rough estimate per pot lands at 0,2 NOK ($0.02).

- Nutrients and pH-fluids costs are insignificant. Our calculations of fertilizer cost per plant came to 0,0006 NOK.

Other operating costs

Next to growth materials, the most substantial cost for indoor farming is electricity for lighting, ventilation, dehydration, and circulation.

Regarding lighting costs, you can find detailed estimates in our article about why LED is best for indoor farming.

As for ventilation, dehydration, and circulation, our calculations coincide with reported numbers from vertical farming companies worldwide. This tells us that the power consumption from these fixtures usually amounts to about 30-40 percent of the energy used for lighting.

In other words, the expected ventilation, dehydration, and circulation cost is about 35 percent of the lighting costs (in larger vertical farms).

What is the best location for a vertical farm?

If you’re planning to start a vertical farm, your number one priority should be to find a well-isolated space that is naturally sheltered from sunlight. Growing in naturally cool environments has much potential for reducing vertical farming startup costs.

Another thing to keep in mind is to find a place with an infrastructure that supports plant growth. Well-integrated solutions for drainage, watering, ventilation, dehydration, and power will significantly aid your progress.

Be on the lookout for uneven floors. Ideally, the floors should be as even as possible. This makes the daily chores at a vertical farm much more manageable.

Avisomo’s vertical farming startup costs include our expertise!

Avisomo’s vertical farming solutions include access to the Avisomo online platform, where we regularly put out new plant recipes and updates on methods for indoor farming. This way, you’ll stay ahead of the game with the best plant recipes available and the latest tricks of the trade.

The result of vertical farming depends on your ability to run an efficient operation. There are many variables to consider, for instance, what markets you are targeting, how high your electrical bills get, what type of space you use, and how many people you employ.

No matter what your variables are, Avisomo is there to aid you with our know-how, experience, and technology. Each Avisomo customer joins our league of partners. Together we’ll ensure that your farm is profitable and scalable and that your vertical farming startup costs are as low as possible.

Got more questions? Feel free to contact us at Avisomo. We are always happy to help, advise, and chat about our favorite pastime: Vertical farming.

Resources:

AgFunderNews: The economics of local vertical & greenhouse farming are getting competitive

Agweek: The cutting-edge technology that will change farming

Crumpacker, Mark: What Are the Keys to Success for Vertical Farms?

Hortibiz Daily: Vertical farming and the future of automation in agriculture

HortiDaily: The CEA space expected to grow heavily in 5-10 years

MDPI: State of the Art of Urban Smart Vertical Farming Automation System: Advanced Topologies, Issues, and Recommendations

Microsoft: Indoor vertical farming in Asia and beyond: Digging deep in data