Vertical plant factory development is spreading worldwide but has yet to become mainstream. Why? Because vertical plant factories have not been cost-effective enough until now!

How does Avisomo outclass other vertical plant factory solutions? By combining industrial standards, a cutting-edge growing concept, and revolutionizing automation methods. The result is increased vertical farming profits and, hopefully, a lasting improvement in the plant factory industry.

As far as all our research can tell,

Avisomo has designed the most cost-effective

plant factory solutions the world has ever seen!

We started by asking ourselves, «what are our biggest expenses, and how can we cut them»? The issue was solved by applying advanced automation techniques by IoT and robotics. But to fully grasp the specifics, we first need to address a few plant factory basics:

Contents:

- What is a plant factory?

- What are the plant factory operational costs?

- Avisomo’s vertical plant factory automation

- The vertical plant factory business model

- Vertical plant factory guide to market domination

We know it’s bold to claim that Avisomo’s solutions foster the most cost-efficient plant factories worldwide. Still, we believe it to be true. We made a formula for success based on the returns we got on our plant growth test site. The key is to think big.

Related article: What does vertical farming mean to investors?

What is a plant factory?

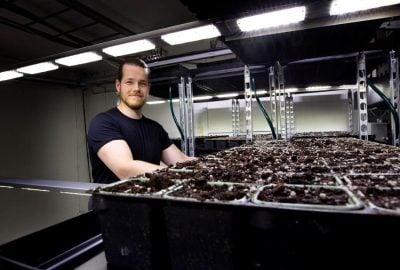

The definition of a plant factory is a closed environment for year-round plant growth. All conditions are artificial, which allows for precise production control. Modern plant factories frequently apply vertical farming methods such as this.

Be aware that there is a difference between your average vertical farm and plant factories. Avisomo’s solutions will yield great results for smaller farms, but big returns require big production. We regard a plant factory to hold at least 2500 growth stations.

By controlling light, irrigation, ventilation, and nutrient flow, your crops never fail, and bad weather conditions never hinder your plant growth. The only real problem is your expenses, but Avisomo has found a solution. We’ll get to that momentarily.

What types of plant factories are there?

There are two types of plant factories: One relies on artificial light, the other on natural light. When using artificial light, your plant factory has a closed environment. When using natural light, it is a giant greenhouse.

Read more about the differences between vertical farming and greenhouse farming in our article library. We recommend a vertical plant factory if you aim to overtake your local plant production market. Here is what you need to consider:

What are the plant factory operational costs?

The operational costs in a plant factory are largely affected by two things: Energy consumption and workforce. Success always hinges on the cost reduction of these two factors.

The best strategy to maximize returns is to automate production as much as possible and apply advanced LED control. LED grow lights are recommended for optimal plant growth but are costly. Fortunately, you can manage fine without much workforce.

Avisomo’s solutions are designed for fully automated plant production. This makes any vertical plant factory more cost-effective than its competitors. If you also reduce your vertical farming energy consumption, your plant factory will be unstoppable.

What does it cost to start a vertical plant factory?

There is no hiding it; vertical farming startup costs are high, which is why it is crucial to stabilize income quickly. At Avisomo, we have conducted many experiments and trials to ensure that our partners earn back their investment as soon as possible.

Average plant factory startup costs come from building acquisition/construction, machinery purchases, and lighting/air-conditioning installment. In addition, you need top-of-the-line computer systems and software to optimize automation processes.

How much this amounts to depends on location, the current energy prices, and the deals you can broker with your suppliers. Contact Avisomo to get an estimate on how much your plant factory startup will cost.

Avisomo’s vertical plant factory automation

The foundation of Avisomo’s plant growth solutions is cutting-edge technology and plant science. Our plant factories are controlled by AI and run by robots. We also develop our own plant recipes specifically tailored to our solutions.

With Avisomo in your corner, your vertical farm will be competitive from day one. We’ve tailored our plant factory solutions for automation and lower labor costs than the world have ever seen before.

We automate seeding, feeding, lighting, irrigation, ventilation, harvesting, internal transport, packing, and warehouse stocking. Labor is mainly limited to planning, marketing, computer surveillance, and customer service.

Does it sound too good to be true? To be honest, a vertical plant factory with 2500 growth stations will never be empty. This size production requires labor, but our solutions demand less workforce than any other.

We make use of the most elaborate automation techniques known to man. By doing so, we make plant factories that can produce more for less, enabling them to lower their prices, outcompete their rivals, and conquer market shares.

Related article: What is VPD / RH? Vertical farming’s hidden success factors!

The vertical plant factory business model

The point of a plant factory is to capitalize on vertical farming’s full potential. The goal is to enhance v-farming profitability. This is achieved by cranking production to the max and simultaneously turning down the expanse faucet.

The combo of large-scale and cost-effective production is the key to market domination. In addition, well-planned strategic moves in the startup phase are vital for any plant factory’s survival.

Choosing the right location is essential

Choosing the right plants to grow is equally so

That doesn’t sound so hard, does it? Well, plant scientists have spent the better part of a decade trying to limit vertical farming expenses. Recent developments in LED and IoT technology made Avisomo’s solutions possible.

The best LED grow lights on the market might be costly, but their lifespan makes them most cost-effective in the long run. On top of that, LED grow lights offer unparalleled light control, which is crucial for plant growth optimization.

We provide turnkey solutions and help customize them to your needs

Advanced automation by IoT is an integral part of our solution. It makes plant optimization easily manageable for anyone. More importantly, it drastically reduces your labor needs.

Our business model is based on cutting energy consumption and workforce expenses to the bone for all our partners. We achieve this by adapting our in-house solutions to each factory’s conditions. Our expertise is part of the package.

Vertical plant factory cost and returns

Estimates of plant factory viability tend to first ask, «How much does vertical farming cost?» Though this is important, we think it’s even more important to question how profitable your plant factory can become.

The startup cost will be high no matter what, but your path to profitability can be shortened, and your returns can be maximized. We at Avisomo are happy to help startups of any size, but to be frank, bigger is better.

It will probably be viable for small-niche v-farms to do good business when vertical farming technology is improved. However, right now, significant returns require investment in plant factories, which is why we specialize in large-scale productions.

Related article: Why is CEA growing so fast? (Controlled-Environment Agriculture)

The more plants you can produce, the better prices you can offer, and the bigger sales you can make. Not only that, but big sales enable you to broker better deals with suppliers, transporters, and customers.

We are still in the early stages of plant factory technology development, but the market evolves quickly. Soon, there will be better sales channels, more promotional options, and larger customer bases.

At Avisomo, we are confident that the vertical farming business will soon explode. Meanwhile, you need to be detail-oriented to succeed in the industry since every little thing matters when trying to maximize ROI in a burgeoning market.

For some real numbers on earnings, check out Vertical farming economics in a nutshell

Vertical plant factory guide to market domination

Because vertical farming is a young industry that evolves much from year to year, plant factory costs and returns depend on adaptability. It is a double-edged sword because it demands rapid upgrades but offers new financial earning opportunities.

If you invest big and establish a brand right now, you might still become a senior player in the industry of tomorrow. That said, the vertical farming markets in Asia and America are already very competitive, and the rest of the world will soon follow.

There is still room for new players all over the world, though, with perhaps the exception of Japan, which pretty much established the plant factory industry before anyone else. Let’s round off our article by learning from the best in Japan: Spread.

Spread is one of the biggest vertical farming companies in the world, and they have been so kind as to share their business strategy. Here are the best tips from Spread and us at Avisomo, compiled into a handy list for all plant factory cadets:

Read more about Spread in our article «Vertical farming – From concept to profit»

Top 10 steps towards plant factory market domination

- Think big! A large-scale plant factory is your ticket to success.

- Learn the tools of your trade. Plant optimization is crucial for profit.

- Make sure that your plant factory is located near its customers.

- Build your startup on leafy greens but be prepared to branch out.

- Invest in the best LED grow lights on the market.

- Automate the operation as much as possible to cut costs.

- Expand your business quickly with a tailor-made plant factory system.

- Uphold good synergy between production, development, logistics, and sales.

- Ensure good workflow between your harvesting team and your transporters.

- Never lose focus on branding and marketing.

Please forgive our shameless pitch at number seven but take it seriously. We believe in what we do, and part of Avisomo’s vision is to help all our partners succeed. Not only that, but we are confident that our solutions are top-of-the-line worldwide.

Notice how we prefer the term «partners» as opposed to «customers». We like to think of anyone who uses our solutions as a partner. We are all working towards a shared goal. Your success is our success and vice versa. Hope to hear from you soon.

Contact Avisomo anytime for a chat about vertical farming, plant factories, and the future of our food industry. We are happy to share our expertise and give estimates. We might even have a special offer on our solutions for a few lucky callers.

Resources:

Agritechture: Newly-Launched Vertical Farming System Is Focused On Achieving Profitability Faster

BusinessWire: Research and Markets: Global Vertical Farming, Plant Factory Market

Cambridge HOK: How much does vertical farming cost?

Frontiers: New Business Models for Modular Urban-Vertical Farming

Kubota: “Plant Factories” Offer a New Form of Food Production

MDPI: Plant Factories: A New Playground of Industrial Communication and Computing

Pure Greens: How to Estimate Vertical Farming Costs

ResearchGate: Vertical Farm 2.0: Designing an Economically Feasible Vertical Farm

Springer Link: Production Cost Analysis and Production Planning for Plant Factories