Is vertical farming sustainable? Plant factory technology has long since been called into question. Like the Tesla cars, vertical farming is accused of leaving a carbon footprint that isn’t outweighed by its green aspirations. Even so, plant factories make big profits, which incites international corporations and investors to seek out and invest in more sustainable solutions.

Energy consumption costs haunt many burgeoning businesses with green ambitions. The lack of battery technology innovation hindered Tesla’s sustainability. Likewise, power-demanding lighting technology and extensive operational costs have held back plant factories’ profitability.

However, the cost of LED plant lights and their technology has plummeted as production became increasingly streamlined. This development has paved the way for worldwide plant factory profitability.

Related article: The best vertical plant factory solutions right now!

As a result, some of the biggest companies in the world, like Microsoft, Google, and Philips, invest vast sums in vertical farming startups and the development of plant factory technology. Their goal is to make vertical farming fully sustainable.

When they achieve this, which we expect will happen soon, the result is further decreasing investment and operational costs.

Contents:

- How plant factories can heal the world

- Plant factory technology promotes vertical farming sustainability

- How to make vertical farming sustainable on all fronts?

- Plant factories shaping our future food production

- What is needed to start a vertical plant factory?

- Future plant factory technology: Vertical farming 2.0

How plant factories can heal the world

Even before scientists succeeded in lowering LED-plant lights’ energy consumption, plant factory technology offered a solution to one of the biggest environmental problems today: Land degradation.

In April 2022, United Nations published a report stating that human activities have damaged 20-40% of all arable land on the planet. As a result, G20 has resolved to reduce land degradation by 50 percent by 2040.

Furthermore, 115 countries have committed to restoring 1 million hectares of arable land. At the same time, we need to increase our food production for an ever-growing global population. Plant factories make both goals possible.

Relevant article: The plant factory cure for environmental breakdown (coming soon)

Plant factory technology promotes vertical farming sustainability

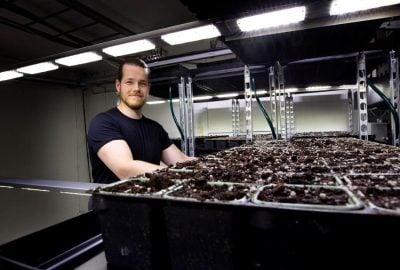

The most evident difference between vertical farming and traditional farming is that plant factories don’t require arable land. A suitable building, like an abandoned factory or office complex, has the necessary space to start large-scale plant production.

Plant factories use 90 percent less arable land than traditional farming.

As mentioned, energy consumption still poses a big challenge for plant factories when it comes to environmental sustainability. That said, plant factory technology promotes many green solutions that pose significant problems in traditional farming.

Plant factories hardly ever use chemicals and pesticides, for one, since the closed environment provides ample shelter from bacteria and pests. Secondly, plant factories recycle much of their nutrients and almost all their water.

Vertical farming spends 70-95 percent less water than other farming.

In other words, there is no spillage from plant factories, no chemicals applied, and minimal use of fertilizers, all of which make vertical farming largely sustainable. The only real issue is the lagging LED technology, but we’re close to a solution.

How to make vertical farming sustainable on all fronts?

Plant factories’ most prominent cost drivers are energy use and labor costs. So far, this has hindered them from making vertical farming fully sustainable, both in the economic and the environmental sense of the term.

As a result, the worldwide plant factory industry has halted somewhat. Cost-cutting is the key to furthering global expansion. How so? Well, energy costs directly connect to plant factories’ carbon footprint.

In large parts of the world, energy is bought from coal-fired power stations. These power stations emit massive amounts of pollution. To reduce such emissions, scientists try to design more efficient LED-plant lights and better methods for controlling the amount of light spent on plant growth.

Lowering the energy consumption will result in plant factories buying less electricity from coal-fired power stations. Such strategies are already being implemented. Further improvement will make vertical farming fully sustainable, both from an economic and environmental perspective.

Many researchers are also looking into solar energy as an aid for vertical farming sustainability, which we talk more about in our article on vertical farming research.

Plant factories shaping our future food production

As mentioned, large companies worldwide have realized the potential of vertical farming. This is why industry giants like Microsoft, Google, SoftBank, IKEA, and Walmart invest heavily in the vertical farming industry and spends billions on plant factory technology development.

Most of these companies are driven by sustainable ideologies. However, none of them would be able to spend these kinds of resources if it weren’t for profitability potential. Japan and USA have taken the lead and developed stable plant factory industries.

Countries worldwide follow in their footsteps because they all see the potential for sustainable food production with excellent profit margins. But plant scientists aren’t working for sustainability alone; they aim to make our plants healthier and tastier.

Example: Mitsubishi’s plant factory initiatives

Mitsubishi Chemical Group has developed a so-called «three-way satisfaction» plant factory system. This system aims to promote the best interest of three key target groups: Plant producers, consumers, and the global environment.

Mitsubishi first aim to establish indoor plant growth that is not affected by nor contributes to negative climate changes. The second sub-target is thoroughly optimizing plant growth and producing better quality plants for consumers.

Finally, Mitsubishi aims to develop a plant factory system that promotes farmers’ safety, security, and stability. Via automation and cost-cutting, Mitsubishi hopes to make a healthy and sustainable industry for everyone, including future generations.

In line with Mitsubishi’s strategy, Avisomo aims to heighten plant factory standards by taking vertical farming automation to a new level. When we achieve our goal, plant factories will be more profitable than ever before.

Read more about the Avisomo vertical farming system

Investment costs have made investors hesitate for decades. However, technological strides are quickly making vertical farming sustainable, both in the economic and environmental sense of the term.

What is needed to start a vertical plant factory?

In short, you need to invest in a sizeable and functional vertical farming system and find the perfect location for it. The site can be anything from abandoned factories to office buildings, and the system must be top-of-the-line.

To start a plant factory, you will need lighting, irrigation, ventilation, fertilization solutions, sensors, software, plant recipes, packing/storage facilities, and robotics. The price will vary depending on farm size and location, but startups are costly.

That said, once plant factories are set up and production runs smoothly, the cost radically drops and remains lower than any other type of plant production. This is because plant factories are synonymous with plant growth automation.

Large-scale plant production and automation go hand in hand since large sales make up for the high initial investment. Automating smaller plant farms might also be profitable, but it will take longer to return your investment and get the earnings rising.

This is why plant factories depend on strong investors, well-planned strategies, and highly dedicated partners. Avisomo can help you with the two latter points, which might just help you convince and land a good investor.

Future plant factory technology: Vertical farming 2.0

Plant scientists are very busy these days, especially the ones looking to make vertical farming sustainable and plant factories more profitable. The exciting part is that many plant factories have already turned a profit and that sustainability will increase their revenue.

The development of AI solutions for vertical farming is a focus area for many researchers. Better AI solutions will improve plant optimization and automation. Additionally, it will enhance light control, which makes a big difference in making plant growth sustainable.

The idea is to use AI to find the perfect light balance, spending minimal energy on optimizing plant growth. This balance continuously improves in line with the development of more cost-effective grow light designs.

The future of vertical farming looks bright, much due to the constantly improving plant factory technology. The way things are developing these days, it is only a matter of time before vertical farming becomes sustainable on all fronts and changes our food production practices for the better.

Related article: What is VPD / RH? Vertical farming’s hidden success factors!

Resources

DW: Turning the tide on land degradation

Mitsubishi Chemical Group: Plant Factory: Sustainable agriculture beneficial for the environment, consumers, and producers

United Nations: Global Land Outlook 2nd edition

Vertical farming planet: Countries Using Vertical Farming