An essential step towards success in vertical farming is to take control of your economics. You need to create and maintain a good balance between capital, operating costs, and earnings. Let’s take a look at the most critical factors of vertical farming economics.

Technological advances, climate changes, and increasing food demand rapidly accelerate the CEA business (Controlled-Environment Agriculture). However, many vertical farms struggle to make ends meet, which has raised questions about the profitability of CEA.

Relevant article: Why is CEA growing so fast?

Indoor agriculture technology has existed for 20 years or more. However, not until recently has it been possible to turn it into a major business. CEA has gradually gained traction over the last decade or so, but it still takes skill to balance vertical farming economics right.

Vertical farming is still a relatively small niche in many parts of the world. However, some countries, like Japan, Singapore, and the United States, have turned it into big business. The question is, can anyone make a profit from vertical agriculture?

In theory, yes, but there are many things to consider. For example, the financial potential of your vertical farm depends on factors such as size, location, demand, target customers, and more. This article will take you through the basics and give you some pointers to keep in mind.

Keep an eye on our blog and sign up for our newsletter. Then you’ll get notified when we publish our upcoming business plan template for vertical farms.

The questions you need to ask when starting

When setting up a vertical farm, you need to assess the operating cost and resources thoroughly. Resources must include calculations such as labor, supply chain, sowing, and nutrients.

To make the calculations, you need to ask yourself some much-needed questions like;

- How is your location? Is it a hot or cold climate?

- How large will your crops be?

- What is the growth period for the specific plants you will cultivate? This determines how many crops you can harvest in a year.

- Can your equipment recreate optimal conditions for the plants at low operating costs?

- How much return can you expect?

Each of these questions requires that you look at the details of your production line and make a correct calculation of the cost of your infrastructure, such as the seeds, equipment, machinery, lamps, substrate, etc.

You must also decide whether you want a fully automated or semi-manual production. Of course, you’ll need labor either way. The difference is how many you have to hire and what kind of knowledge or skills they need.

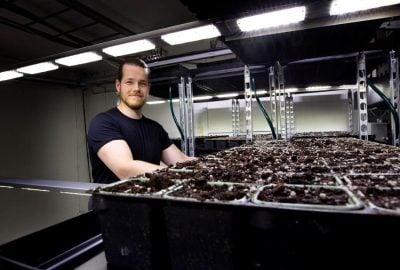

When we developed the Avisomo-system, we planned for you to get started small and scale-up. This way, you can start a small manual production to familiarize yourself with the system and then invest in larger facilities with appropriate automation.

This approach increases the likelihood of success considerably. You get the opportunity to qualify the market in advance by delivering samples and ensuring stable production before you take on significant investments.

Investor interest affects vertical farming economics

For those who succeed in vertical farming, the rewards can be considerable.

A research report from Emergen Research from 2020 shows that the global market value of vertical agriculture is 2.9 billion USD, with an expected growth of 20% per year. It is expected that the sector will be worth $ 11.7 billion by 2027.

Naturally, this has piqued the interest of that many investors.

In the United States, some big investments have been made in companies such as Brightfarms and Plenty in recent years. In 2020, even the government of Abu Dhabi invested $ 100 million in vertical agriculture. These are companies that will compete with the existing food production system.

But for every success story, there are several that have ended up with such high capital costs that it will take them decades to create profitability. Or even worse: They have unnecessarily high operating costs, making it impossible for them to achieve profitability.

Avisomo has excellent solutions for getting started with vertical agriculture to increase the efficiency of your farm or create a new department elsewhere.

In addition, we are in contact with several investors who would like to invest in this industry. It’s seen as a safe investment because everyone needs food!

Vertical farming profitability

Creating profitability in vertical farming is about having a good plant factory.

A good plant factory is located in a cool and well-insulated building, which results in lower operating costs.

You will also have to depend on good cooling and circulation to reduce the heat from the lamps and transport away moisture that the plants emit.

Electricity costs are therefore affected by how well insulated and how naturally cool the premises are, cooling, ventilation, and the efficiency of the lamps.

Avisomo uses market-leading LED grow lights that, when used correctly, provide lower costs than other lamps.

There are many different solutions for vertical agriculture when it comes to stacking plants. Some suppliers have specialized solutions for specific plants, while others have solutions that can be used for many types of plants.

Avisomo uses standardized trolleys that are already used in Norwegian agriculture. This significantly reduces investment costs since you can use the same trays and pots you are used to.

We will also take a closer look at:

- The main reason for profitability in a plant factory

- Use of light

- Climate control

- Labour

Related article: How to reduce vertical farming energy consumption?

The game-changer that turned plant factories into big business

Many exponential developments have contributed to better achievements in vertical agriculture in the last ten years alone. LED lamps have become significantly better, renewable energy has become considerably cheaper, and we’ve seen the same development for air conditioning and dehumidification.

This is why vertical agriculture or plant factories have gone from red figures to solid profits in many places.

Plant factories are known to be massive investments. Avisomo has addressed this by offering a cost-effective way to get started: The revenue is higher than the cost, and the investment is replaced with regular monthly expenses instead. We also use standardized components to keep costs low.

The fact that the technology is more accessible than ever has contributed to making such models possible.

Grow lights are the key to good vertical farming economics

One of the biggest challenges in creating profitability in vertical agriculture is that different plants will need different lighting conditions. Even the slightest mistake can lead to increased costs and lower returns, which is what you want to avoid.

Take LED lamps. This type of light can account for 30% of start-up costs, and depending on other factors, power can account for anything between 25 – 65% of your operating costs. So, just optimizing the light spectrum of your crops will reduce operating costs majorly.

In vertical agriculture, we often talk about how many micromoles are needed for a plant to develop properly. If, for example, you give the plants 200 micromoles and, in reality, they only need 180 micromoles, you are simply wasting 10% of the light you’re using.

More importantly, the light should always hit the plants. The photons that hit something other than the plant leaves are just a waste of energy.

Therefore, you must choose suitable lamps from the start. Don’t fall into the position where the lights use more energy than they need. And ensure that you work with someone who understands the technology, the product, and the current data.

Relevant article: Why is LED grow lights best for vertical farming?

Technological advances and replacement of lamps

In 2021, the LED industry reached a new peak. Knowing that the next generation of LED’s will appear on the market in a few years, we’ve taken into account that the older lamps must be replaced. When they are to be replaced, it must be possible to do so as smoothly and effortlessly as possible.

At Avisomo, we’ve made it extremely easy to replace the lamps you no longer need. It will require very little time, and most importantly, it will not disturb the production process.

When new lamps arrive, you can buy them directly from us with the same fastening mechanism as their predecessor. You will never be left with a bunch of lights you do not need. We then take the used ones back and give them a new life!

It’s good to note that replacing lamps is a part of the operating costs that must be balanced against the capital costs and earnings to create great profitability in vertical agriculture.

Let the laws of physics help you create profitability

By having specialists on your team, you can avoid mistakes and increase your profit margins. Specialists can help you create different spectrums that use minimal energy and give you the intensity and spectrum your plants need to grow – no more and no less.

Also, remember to implement due diligence when it comes to LED lamps. Cheap is not necessarily best. Cheap lamps may have lower CRIs, poor phosphor and color shades, and will not provide the right amount of light.

One of the biggest pitfalls in the LED industry is that the diodes and resistors are soldered together too tightly. This is done to make the lamps as small and compact as possible. Unfortunately, this creates more heat in some places than necessary, which drastically reduces the lifespan of the lamps. The heating of the circuit boards and poor heat dissipation are the main reasons for a short lifespan.

Therefore, it is essential not to be seduced by a supplier but to look at its science. Light has a weaker effect over long distances, and you must investigate whether what the manufacturer promises is possible according to the laws of physics.

Related article: Vertical farming research

Climate control equals cost control

In vertical farming, you have complete control over the lighting conditions. You also have total control over the climate. Since vertical farming takes place indoors, you also get a degree of built-in pest control as an extra benefit.

In addition, avoiding the cost of pesticides gives you greater control over your crops. This is how you get predictability and how you can plan your crops carefully.

This is a big advantage as we are likely to experience more extreme weather in the future. Both extreme drought and extreme rainfall can damage crops or reduce production predictability.

Vertical farming is not affected by such extreme weather and can increase your bottom line.

With the help of climate control and access to light and nutrients, you can grow the plants as you wish. For example, you can influence whether the plant grows tall or in a more compact shape and whether it grows more or fewer leaves. You can also control the aroma and nutritional content of the final product.

All of these are things we can do or have done in our test facilities. The most crucial factor is the intensity of light and color spectrum, but fertilizing the plant at different stages of the plant’s growth also affects the result.

How does labor affect vertical farming economics?

Labour is not cheap, so you need to limit your labor needs as much as possible. First, you need to find out how much labor you need. This depends on several factors.

Number of levels

Some systems have many levels, which can seem wise since you will get more square meters of cultivation area per square meter of premises. However, this may not always be the case.

The disadvantage of many levels is the limited access to the higher levels, which will require expensive equipment to inspect and harvest the crop. This also means that there must be enough space between the shelves, which reduces the cultivation area.

In addition, employees must work at height and operate equipment, which also entails costs for training.

The Avisomo-system is built so that the plants can stand tight and be inspected without additional equipment. You can also automate most of the production as well.

Automation leads to fewer employees

If you invest in full automation with a sowing machine, robot, and harvesting line, you can significantly reduce the cost of labor and increase profitability.

The difference between manual and automated production is quite drastic:

With complete automation, one worker can handle 550 stations. Then you only need to monitor the production and take measures if problems arise.

On a farm without automation (but with innovative tools), one person can handle 80 stations.

Therefore, labor is an important factor to consider when trying to create profitability in vertical agriculture.

What should you cultivate to strengthen your economy?

When it comes to what to grow, you have many choices.

Although it’s technically possible to produce any plant, some plants give higher yields than others. Therefore, to ensure profitability, you should focus on crops that grow fast and have a high market value.

These plants will be the most cost-effective.

Therefore, many of those who run vertical farming facilities focus on high plant density and fast-growing crops where the whole plant can be sold, such as herbs and lettuce. These plants typically need fewer resources to grow and can be sold at a higher margin than, for example, root vegetables.

Another option worth exploring is to take advantage of the high germination rate and the increased rate you can achieve in a controlled environment. You can sell small plants to commercial producers who focus on field and greenhouse production.

All-year-round producers need good quality small plants, and there is a desire for more small plant producers in Norway as most people buy such plants from abroad with a high risk of transport damage, diseases, and other problems.

Organic crops might be the future

If you want increased profitability in vertical agriculture, you must sell your products at the right price.

Producers engaged in vertical farming have already begun to increase prices, but it is also crucial to find the right price point for each crop.

Sales of organic foods are also increasing as consumers become more aware of what they eat and what effect the food has on their health. As a result, the organic food market is predicted to be worth $ 320 billion by 2025.

The increased demand for organic products is also one of the reasons why it is predicted that the vertical agricultural sector will increase to 11.7 billion USD by 2027.

Since vertical farming provides your crops with natural protection against pests and plant diseases, this is an excellent production method for growing organic produce.

In the long run, organic food from vertical agriculture will cause organic food prices to fall, but this will make production more profitable because people will buy more organic produce.

The long-term perspective is important

Although start-up costs can be high, it is important to look at the long-term perspective regarding climate concerns, less accessible land areas, unpredictable weather conditions, climate change, and the limited resources we have to secure food for the ever-growing world population.

Even though we are now starting to see some companies with great success in which a lot is being invested, we still have to be wary.

CEO of British Crop Health and Protection, Fraser Black, compares the industry with electric cars and believes the industry is following the same trend. More people are starting to make a profit, and the market is developing in a positive direction. Vertical farms can compete with more traditional production methods, especially in northern countries such as Russia, Finland, Sweden, Norway, and Canada.

A changing market will increase profitability

As mentioned, the market is constantly evolving, and the benefits of vertical agriculture make it interesting for many private equity funds and venture capital funds to invest in the sector.

Some of the benefits are that you save costs on water and pesticides, while you can harvest crops throughout the year and grow more per square meter.

Related article: Vertical farming vs. traditional farming

For the customers, some of the advantages are that you can make the produce more nutritious. The crop is also often fresher when it arrives on the shelves due to a shorter transport route and more predictability in production. This also leads to less wastage because the products have a longer shelf life.

It will also be cheaper to run your vertical farm when you have established your production, gained more knowledge, and the technology develops further. This also makes it easier to increase profitability.

This is something we have a strong focus on in Avisomo. Therefore we designed our system to make it easy to always take advantage of new developments in the market and technology.

The system can be further developed and upgraded but never needs replacing!

Take control of your vertical farm’s economy from the start

To ensure profitability from the beginning, you must think carefully through all aspects of production.

If you establish the right kind of production for your geographical location and your market, you will be able to create profitability from the start.

Related article: Vertical farming – From concept to profit

You need to choose suitable systems, plants, and much more to manage this. At Avisomo, we have experience with this and can help you with the choices you have to make.

Ensure profitability with Avisomo’s vertical farming system

Our system makes it easy to take control of vertical farming economics. By relying on modular units that can be connected, we reduce investment costs and standardize production figures. This makes it easy to calculate the profit!

| Plant type | Production cost | Labour and equipment | Sales price |

| Herbs (8 cm pots) | 3 NOK | 3,5 NOK | 12 NOK |

| Salad (8 cm pots) | 3 NOK | 3,5 NOK | 11 NOK |

| Microgreens | 6 NOK | 3,5 NOK | 25 NOK |

In an Avisomo cultivation station (standard), you can accommodate 3 CC trolleys with four levels. This corresponds to a cultivation area of 11 sqm. In this area, you can fit 480 pots with a distance of 15 cm between the pots (as recommended by NLR).

Suppose you are growing herbs in peat that are sold in pots. Pots, peat, and seeds can cost between 2 and 3 NOK per pot, depending on how you choose to do it. Then there are operating costs in relation to lighting, ventilation, maintenance, and staffing. Many things come into play here, but these variables usually come to between 3 to 5 NOK per pot. If you assume a bulk price of 12 to 15 NOK per pot, you have a solid profit.

The profit is significantly better if you can sell directly to consumers, but there may be increased costs in connection with sales and the market.

These figures are experience figures from our test facility at Skreia, where we currently produce a variety of herbs, lettuce, and microgreens for the local market in Oslo.

| Plant type | Production time | Profit per month |

| Herbs | 30 days | 2.640 NOK |

| Salad | 30 days | 2.160 NOK |

| Microgreens | 10 days | 23.040 NOK |

If you have 1/3 of each plant type, you will be able to achieve 9,290 NOK in profit per station.