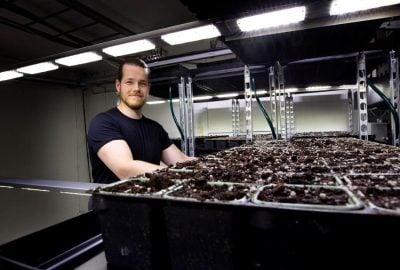

Plant factories use vertical farming systems for plant production. Their financial success depends on how well the system works for their operation. Avisomo aims to provide the most cost-effective system on the market today. Our Avisomo Growth Station™ is developed to ensure the success of any vertical farming operation.

The main benefit of Avisomo’s vertical farming system is its adaptability to all kinds of production. Our modular vertical farming system will promote profitability regardless of the size of your vertical farm or the plants you choose to produce.

We specialize in the automation of large-scale plant production. The Avisomo vertical farming system automates more processes than most other systems. As a result, plant factories get the best cost-cutting and returns on investment possible.

Related article: The best vertical plant factory solutions right now!

Contents:

- The most flexible vertical farming system you can get

- Avisomo’s vertical farming solutions and our partners

- Grow all kinds of plants with Avisomo’s vertical farming system

- Automate all stages of your plant production

- How to use the Avisomo vertical farming system?

- The Avisomo vertical farming system in a nutshell

The most flexible vertical farming system you can get

Avisomo’s vertical farming system is designed to be flexible and straightforward. We use CC trolleys since they are already a standard in the plant industry. In addition, our system is modular, which gives plant factories many options.

The CC trolleys are highly adaptable and can accommodate many kinds of trays, pots, and equipment. The trolleys don’t have any built-in technical components, which promotes flexibility, efficiency, and profitability.

Related article: What does vertical farming mean to investors?

The trolleys don’t need to be attached to anything. Place them where it suits you best. Once the trolleys are in place, you fit them with sensors and control units. Then you tell the control system where the trolleys are and what they carry.

The control system software helps you keep track of the plant growth and constantly works to improve your results. This is the basics of the Avisomo Growth Station™ concept; to simplify and automate both plant growth and production logistics.

Moving and refitting the Avisomo growth stations after installation is easy. You can replace them by hand or use robotics. No matter what kind of vertical farm you have, your production will be simplified by our flexible solution.

Avisomo’s vertical farming solutions and our partners

As mentioned, we’ve developed the Avisomo Growth Station™ and its concept, but we couldn’t have done it without good partners. These collaborations also enable us to streamline all aspects of plant production.

For instance, via our partners, we can offer washing machines that can clean entire CC trolleys in one go. Additionally, we can provide manual and automatic sowing machines to ensure that your plant production is efficient from day one.

Related article: Vertical farming – From concept to profit

We also provide semi-manual and automatic harvesting machines and AGV robots for automated logistics. In short, we provide everything needed to make plant production as efficient as possible.

We offer these products as stand-alone modules. This allows you to pick and choose the most useful tools for your production, and we’re not just talking about hardware. Avisomo also develops plant recipes for optimized plant growth.

Avisomo’s digital plant recipes

Plant recipes are the algorithms that our control system use to maintain plant growth. Plant recipes guarantee replication of your most profitable crop results. Simply put, they are the backbone of the Avisomo vertical farming system.

Each plant has a dedicated plant recipe that controls all plant conditions. AI detects and corrects irregularities and continuously improves upon the results.

The plant recipes respond to the sensors in the CC trolleys and adjust ventilation, irrigation, fertilization, and lighting accordingly. By AI, the system learns which settings work best and keep the plant production optimized and stable.

The plant recipes simultaneously surveil all plants and their various growth cycles, from seeding and pollination to maintenance and harvesting. It tells you when which plants should be moved to new zones and what changes to apply.

The plant recipes are designed to mimic natural conditions. For instance, the control system lets you regulate sunrise, sunset, air circulation, and substrate moisture. The plant recipes also consider substrate types, such as peat, perlite, or Rockwool.

Plant recipes are crucial for plant factories since some buildings create different plant growth conditions than others. That’s why we focus on making easy adjustable plant recipes. Our solution even allows you to make new recipes from scratch.

If you make or change a plant recipe, your work and its effect on your plant growth are saved in the cloud. That way, you can reuse and build on your best accomplishments. Your progress never stops or gets lost.

Avisomo is constantly improving our software. Now we are developing sowing demonstrations, pot size/plant growth distance advisor, and more. We’d love to get your input. Is there something more you wish our software could do? Let us know!

Avisomo’s patented LED grow lights

The Avisomo vertical farming system comes with world-class LED grow lights. Our patented lenses are designed to ensure that the light is evenly spread on all your plant growth.

In recent years, LED technology has radically reduced vertical farming costs. The new lamps use much less energy and optimize plant growth like never before. In short, LED grow lights are best for vertical farming, no question about it!

The Avisomo vertical farming system is limited to four levels in each CC trolley. This is the best way to utilize the LED grow lights since it leaves ample space for optimal lighting and ensures effective plant growth.

Avisomo’s growth stations are designed for easy light attachment. In other words, changing LED grow lights is a breeze. If in doubt, Avisomo will gladly help you get the fixtures and light spectrums right. We strive to give all partners a flying start!

Grow all kinds of plants with Avisomo’s vertical farming system

Modular farming makes plant factories very flexible, not only when it comes to system placement but also plant selection. The system is so flexible that you can even grow many different plants in the same room.

For instance, one part of the vertical farming system can cultivate niche products that cater to the local market. Another part of the system can focus on leafy greens that ship directly to supermarkets and sells in large quantities.

One part of the production might accumulate much-needed profit while another perfects plant growth for larger customer groups. Which plants you should grow depends on your location and the demand of your target customers.

Automate all stages of your plant production

The main benefit of the Avisomo vertical farming system is total control of your entire operation and the possibility to automate everything. We believe that Avisomo’s vertical farming automation is world-class.

Many vertical farming suppliers speak about plant growth automation, but few put their money where their mouth is. Our system keeps track of everything, from sowing and plant growth optimization to harvesting, packing, and stacking.

All elements of your operation can be automized. Granted, sometimes automation needs a helping hand, but we are working hard to improve this. Already, we daresay that our automation solution is among the world’s best.

Sowing automation

The first step towards plant factory stability is to tell the Avisomo control system which seeds you sow. Keep track of this easily with a sticker on the CC trolley and input on your mobile app.

As soon as the system knows which plant you’re growing, it will recognize the growth stage and plan further cultivation accordingly. The control system accounts for many factors, such as pot size, growth medium, CO2 levels, and much more.

Germination without fail

The Avisomo vertical farming system achieves 99 % germination most of the time. This means that, by rigid temperature and humidity control, almost none of your seedlings go to waste, no matter what plants you are growing.

You can easily create a dedicated germination zone by setting up a sprout tent. However, we advise large-scale operations to dedicate entire rooms for this purpose since germination secures plant growth and reduces energy consumption.

You can germinate without grow lights, which is an excellent opportunity for cost-cutting.

For easy germination, we supply pot lids to keep the moisture constant. All you need to do is place the pot in a place with a suitable temperature and let the system take care of the rest.

Plant growth optimization

After germination, the system will inform you which trolleys you must move to the cultivation zones. Thereafter, it feeds a nutrient solution to the plants while optimizing the light in accordance with the various growth cycle stages.

When the plant growth accelerates, the control system will tell you to move the trolleys to yet another zone. Once moved, the system feeds the plants more substantial nutrition, intensifies the lighting, and creates a harsher climate. This is the best way to ensure plant growth optimization.

Smaller farms with lesser crops can set the system to apply a full light spectrum throughout the entire growth period. Then, nutrition becomes the only changing variable.

The Avisomo software takes care of the entire process and notifies you or your employees about any changes or chores that need taking care of.

This is especially useful when you are growing several types of plants simultaneously. Different plants will be in various stages of their growth cycle. The app makes it easy to keep track of everything.

How to use the Avisomo vertical farming system?

The Avisomo control system enables plant growth automation. The control panel gives you all input from your plant growth stations. It also allows you to review plant recipes and adjust settings.

First-time installation

Avisomo sets up the system upon delivery. The number of cultivation stations will be registered beforehand. All you need to do is to register the individual CC trolleys in your system.

Each station is installed with control units and sensors. The control system communicates with these units and sensors to plan irrigation, lighting, and ventilation.

Avisomo’s control system overview screen

The first screen on the Avisomo control panel is called the overview. This is where you’ll find the timeline for your plant growth and the variables in your facility.

On the overview screen, you set and adjust variables such as temperature and humidity. As the name implies, it gives you an overview of the entire operation and the plan that it follows.

The overview screen also informs you when growth stations will become available and which tasks are upcoming in your schedule.

Control system customization

How the production info is displayed on the screen is easily adjusted. For example, if you want, you can emphasize specific stations. You can also put recently installed solutions on top to surveil how well they are working.

To move the various items in your control system screen, you simply drag and drop them where you want. We recommend sorting the items so that your control panel corresponds to the installed stations in your facility.

The Avisomo vertical farming system in a nutshell

This was a brief introduction to the Avisomo vertical farming system. Sign up for our newsletter to stay updated on the latest news about vertical farming. Currently, we are producing lots of helpful content about AGV robotics for automated logistics.

Don’t hesitate to contact Avisomo if you have any questions about our vertical farming system. We are here to help vertical farms and plant factories take off and make their mark in the future food industry.

Related article: Plant factory technology makes vertical farming sustainable!